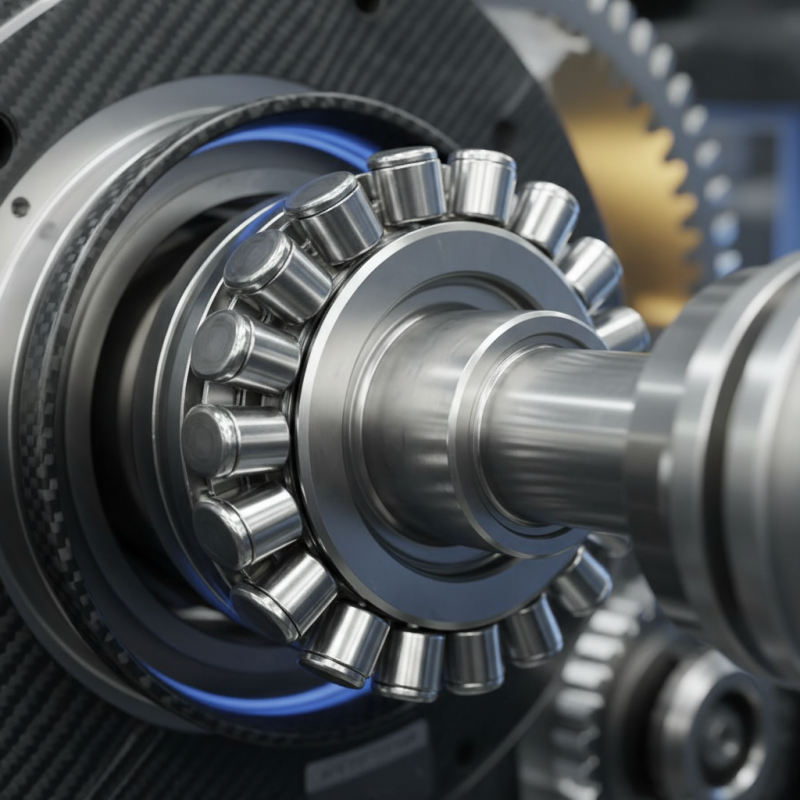

2026 Best Roller Bearings for Optimal Performance and Durability?

Roller bearings play a critical role in various applications, enhancing performance and ensuring longevity. Leading industry expert Dr. Emily Carter emphasizes, "Choosing the right roller bearings is essential for optimal machine efficiency." Her insight highlights the need for precision in selecting bearings that can withstand heavy loads and high speeds.

The 2026 market offers an array of roller bearings designed for durability and performance. Companies face a challenge. They must assess their specific needs carefully. Not all roller bearings are created equal. Some may falter under pressure, leading to costly downtimes. In this evolving industry, innovation must balance with reliability.

As we navigate through available options, users must remain vigilant. Selecting the best roller bearings may feel overwhelming. However, the right choice contributes significantly to operational success. With advancements in technology, the right roller bearings can provide unmatched performance. The quest for excellence continues, but pitfalls remain. Regular evaluation and feedback can guide users toward better choices.

2026 Trends in Roller Bearings: Key Innovations and Technologies

In 2026, the roller bearing industry is witnessing remarkable advancements. One major trend is the integration of smart technologies into roller bearings. These innovations allow for real-time monitoring, enhancing condition-based maintenance strategies. Sensors embedded in bearings can track temperature, load, and vibration. This data helps predict failures before they happen.

Another trend is the shift towards environmentally friendly materials. Manufacturers are exploring bio-based and recycled materials for producing roller bearings. These materials minimize environmental impact and offer similar performance levels. Additionally, advancements in lubrication technology are also essential. Next-generation lubricants reduce friction and enhance durability, leading to longer service life.

However, some challenges remain. While technology offers benefits, complexity can complicate maintenance. Technicians may struggle with diagnosing issues if they rely too heavily on smart features. Furthermore, sourcing sustainable materials may pose a challenge, as not all suppliers are equipped for the transition. These aspects require careful consideration as the industry continues to evolve.

Top Material Choices for Roller Bearings: Steel, Ceramic, and More

Roller bearings play a critical role in machinery. Their efficiency largely depends on the materials used. Common choices include steel, ceramic, and plastic. Each material brings its strengths and weaknesses. Steel is tough and durable. It is, however, prone to corrosion in certain environments. Ceramic bearings, on the other hand, offer exceptional resistance to wear and heat. They are lightweight and can perform well at high speeds. Yet, they are often more brittle and can break under high stress.

The choice of material in roller bearings truly matters. Steel bearings are widely used due to their balance of performance and cost. However, they can degrade if not properly maintained. Ceramic bearings shine in specialized applications, especially in harsh conditions. Yet, they can be expensive and require careful handling. Plastic bearings are lightweight and resistant to chemicals. Still, they may not withstand heavy loads as well as metal alternatives. Understanding these nuances can help you select the right material for your specific needs.

2026 Best Roller Bearings Material Comparison

This chart compares the performance ratings of various materials used in roller bearings, highlighting the optimal choices for durability and efficiency in 2026.

Performance Metrics: Load Capacity, Speed Rating, and Life Expectancy

When selecting roller bearings, performance metrics are crucial.

Load capacity is one of the most important factors. It determines how much weight a bearing can handle without failure.

A bearing with high load capacity can support heavier machinery. However, achieving this often leads to increased size

or weight. Balancing capacity and dimensions can be tricky.

Speed rating is another key metric. This indicates how fast a bearing can operate efficiently.

Higher speeds can improve overall equipment performance. Yet, increased speed often generates more heat.

Heat can reduce the life expectancy of bearings.

So, one must consider cooling measures alongside speed ratings.

Life expectancy is the final metric to evaluate.

It reflects the durability of the bearing under specific conditions. Bearings with longer life may seem ideal.

But, same conditions can vary greatly in practical use. Environmental factors like dust and moisture can affect

performance. Regular maintenance and monitoring are necessary.

All these metrics should guide your decision, ensuring optimal performance and durability.

Durability Factors in Roller Bearings: Corrosion Resistance and Lubrication

When selecting roller bearings, two critical durability factors stand out: corrosion resistance and lubrication. Corrosion can drastically reduce the lifespan of bearings. Environmental factors play a significant role here. High humidity, exposure to chemicals, and temperature fluctuations can lead to rust and degradation. Choosing materials with high corrosion resistance is essential. Some metal treatments can enhance this property. However, not every bearing claims to be truly corrosion-resistant.

Lubrication is another vital aspect of durability in roller bearings. Proper lubrication minimizes friction, which can cause heat and wear over time. Grease and oils come in various types, and selecting the right one is crucial. Factors such as load conditions, speeds, and temperatures affect lubrication effectiveness. Many overlook how often lubrication needs to be checked and replenished. This maintenance is sometimes neglected, leading to premature failure.

In real-world applications, users may encounter issues with both factors. For instance, a bearing might show signs of corrosion despite precautions. This experience highlights the complexity of ensuring durability. Similarly, improper lubrication can contribute to bearing failures. Regular monitoring and adjustments are necessary to avoid such pitfalls. While there are best practices to follow, perfect solutions remain elusive. Continuous learning and adapting is key in maintaining optimal performance.

Market Insights: Leading Manufacturers and Their Competitive Strategies

In the roller bearings market, competition is intense. Leading manufacturers focus on innovation. They invest in research to develop advanced materials. This approach enhances performance and durability. Many companies prioritize sustainability as well. They aim to reduce environmental impact.

Moreover, analytics play a crucial role. Companies utilize data to understand market trends. This helps in making informed decisions. However, not all manufacturers succeed in this strategy. Some overlook the importance of customer feedback. Ignoring users’ needs can result in product flaws.

Effective marketing strategies are essential as well. Brands must communicate their value effectively. Engaging content captures attention. A strong online presence can significantly influence sales. Nevertheless, maintaining consistent quality remains a challenge. Balancing cost and quality is a common struggle for many manufacturers.